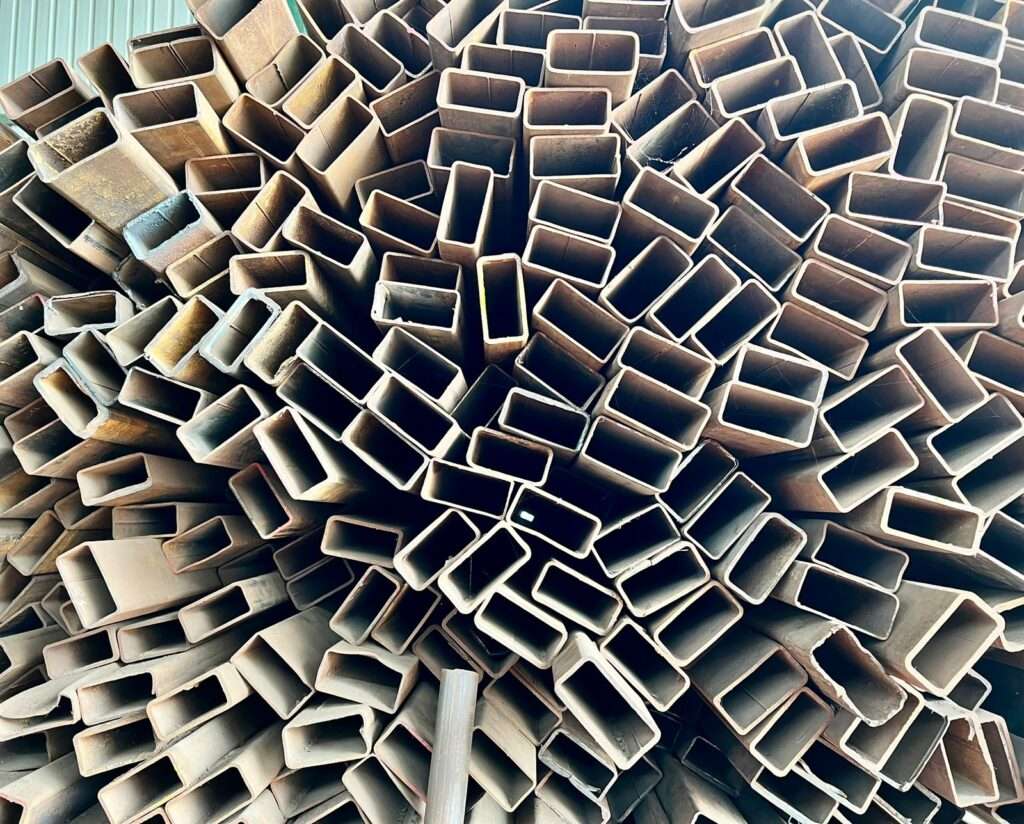

Largest Stock of MS Pipes and Tubes

21/November/2022

Introduction

When it comes to MS pipes and tubes, you want quality and availability. That’s why you need the largest stock of MS pipe and tube available in your area. Here at ABC, we offer the most comprehensive selection of MS pipe and tube that you can find online or offline. We have an extensive range of sizes, grades, wall thicknesses, and more for all your manufacturing needs.

Whether you need a small order to complete a project or large orders for commercial purposes, we have the products to meet any requirement. And because we keep a huge inventory on-hand, you can be sure to get what you need when you need it—no delays, no hassles!

MS Pipe and Tubes Specifications

MS pipes and tubes come in a variety of sizes and specifications. The most common type is the ERW pipe, which is available in a range of sizes and thicknesses. Other types include the seamless pipe, which is available in a range of sizes.

The most common MS pipe sizes are:

• 1/2 inch (15 mm) outer diameter

• 3/4 inch (20 mm) outer diameter

• 1 inch (25 mm) outer diameter

• 1-1/4 inch (32 mm) outer diameter

• 1-1/2 inch (40 mm) outer diameter

• 2 inches (50 mm) outer diameter

The most common MS tube sizes are:

• 3/4 inch (20 mm) outer diameter

• 1 inch (25 mm) outer diameter

• 1-1/4 inch (32 mm) outer diameter

MS pipes and tubes are used in a variety of industries, such as: automotive, construction, oil and gas, plumbing, and more.

MS Pipe and Tubes Grades

There are different grades of MS pipes and tubes available in the market. The most common grades are:

1. Mild Steel (MS) pipes and tubes: These pipes and tubes have a low carbon content (0.17% maximum). They are easy to weld and can be used for various purposes such as plumbing, scaffolding, and manufacturing of car parts, etc.

2. Medium Carbon Steel (MCS) pipes and tubes: These pipes and tubes have a carbon content between 0.30-0.60%. They are strong and can be used for various purposes such as construction, pipelines, etc.

3. High Carbon Steel (HCS) pipes and tubes: These pipes and tubes have a carbon content between 0.61-1.50%. They are very strong and are mostly used for industrial applications such as manufacturing of tools, machines, etc.

Largest stock of MS Pipe and Tubes with Goyal Steel Tubes

Goyal Steel Tubes is one of the oldest dealers of MS pipes and tubes in India. With a vast experience of over 50 years in the field, we have established a strong reputation for quality and service. We offer the largest stock of MS pipes and tubes with various sizes and thickness to meet your requirements. Our products are widely used in construction, oil & gas, chemical, power, and other industries.

MS Pipe and Tubes Application Industries

There are a wide range of industries that use MS pipes and tubes in their operations. Some of the most common industries include:

• Construction: MS pipes and tubes are commonly used in the construction industry for a variety of applications, such as scaffolding, structural support, and plumbing.

• Automotive: MS pipes and tubes are used in a variety of automotive applications, such as exhaust systems, roll cages, and chassis components.

• Manufacturing: MS pipes and tubes are used in a variety of manufacturing applications, such as conveyor systems, material handling equipment, and product packaging.

MS Pipe and Tubes Stockiest in India

There are many MS Pipe and Tube Stockiest in India that one can choose from. However, when it comes to the largest stock of MS Pipe and Tubes, only a few can compete with us. We have been in the business for over two decades now and have supplied our products to some of the biggest names in the industry. Some of our clients include multinational companies, government organizations, and large scale construction projects.

We source our pipes and tubes from some of the best manufacturers in the country who use high-quality raw materials. This ensures that our products are durable and can withstand even the most extreme conditions. Our team of experts supervises every stage of production to ensure that each finished product meets our high standards. We also subject our products to stringent quality tests before they are dispatched from our premises.

We understand that different projects have different requirements, which is why we offer a wide range of MS Pipe and Tube sizes. Our knowledgeable staff can help you select the right product for your specific needs. We also offer customization options so that you can get exactly what you want.

If you are looking for a reliable MS Pipe and Tube Stockiest in India, then look no further than us. With an extensive product range, competitive prices, and a commitment to quality, we are your one-stop shop for all your pipe and tube needs.

Conclusion

We have explored the largest stock of MS pipes and tubes and looked at their characteristics, benefits and applications. This comprehensive article has given you the information needed to make an informed decision when purchasing them for your project. We highly recommend that you look into reliable suppliers who offer high quality products in order to ensure problem-free installation as well as long lasting performance. With this in mind, we wish you all the best with finding the perfect MS pipe or tube for your project!

MS Pipes and Tubes at Lowest Price

29/November/2022

Introduction

If you’re looking for high-quality metal pipes and tubes, then you’ve come to the right place. Whether it’s for a plumbing project or an industrial application, metal pipes and tubes are essential components of any construction or manufacturing process. And finding them at the lowest price can be a challenge.

But not anymore! In this blog post, we provide readers with the resources they need to find MS Pipe and Tubes at the lowest price possible. From online suppliers to local stores, we cover all the bases so that you can maximize your budget and get the best product for your needs. Read on to learn more!

What is MS Pipe and Tubes?

Ms pipes and tubes are one of the most popular choices when it comes to construction materials. They are made from mild steel, which is a type of carbon steel, and they are known for their strength and durability. Ms pipes and tubes can be used for a variety of applications, and construction structures, including plumbing, fencing, and even scaffolding, etc.

MS Pipe and Tube rate in India

In India, MS pipes and tubes are available at very reasonable rates. These pipes and tubes are used in various industries for different purposes. They are durable and can withstand high pressure and temperature. They can be easily cut and welded and are available in different sizes.

MS Pipe and Tubes at lowest price in Sahibabad Uttar-Pradesh

Looking for the best MS Pipe and Tubes Dealers in Sahibabad Uttar-Pradesh? Then you have landed at the right place. We are the leading MS Pipe and Tubes Dealers in Sahibabad Uttar-Pradesh with an extensive range of products. We offer MS pipes and tubes at the most competitive prices in the market. Our products are available in different sizes, thicknesses, and grades to meet the diverse requirements of our clients. We also offer customized products as per the specifications provided by our clients.

Our team of experts ensures that all our products are manufactured using high-quality raw materials and the latest technology. We also stringently test all our products on various parameters to ensure their compliance with international quality standards. Our wide distribution network helps us to deliver all our consignments within the stipulated time frame. So, if you are looking for the best MS Pipe and Tubes Dealers in Sahibabad Uttar-Pradesh, then contact us now!

Goyal Steel Tubes has a low price of MS Pipe and Tubes

Goyal Steel Tubes is one of the oldest dealers and suppliers of MS Pipe and Tubes. We are a 50-year-old brand and have stock of the biggest brand like APL Apollo Steel Tubes, Jindal Steel Tubes, Rawalwasia, and Surya Steel Tubes, The company offers a wide range of products at a very competitive price. The company has a very good reputation in the market and is known for its quality products.

Conclusion

MS pipe and tubes are a great choice for any building project due to their strength, durability, and affordability. We have provided our customers with the lowest prices when it comes to MS pipes and tubes so that they can get the best value for their money. If you're in need of quality materials for your next construction project, be sure to check out our wide selection of MS pipes and tubes at unbeatable prices!

Best Dealer of MS Pipes and Tubes

13/December/2022

Introduction

Looking for the best dealer of MS Pipe and Tubes? You’ve come to the right place! MS Pipes and Tubes are one of the most important products used in industrial construction and manufacturing. They are strong and durable, yet lightweight, making them ideal for a variety of uses.

But where can you find quality MS Pipe and Tubes? To ensure you get the best product, it's important to find a reliable dealer who offers top-notch materials at competitive prices. In this blog post, we will discuss what factors to look for when choosing a dealer for your MS Pipe and Tube needs. Read on to learn about the best dealers in the business!

MS Pipe and Tubes

In the market for MS Pipe and Tubes? Look no further than your Best Dealer! We carry a wide variety of sizes and shapes to fit any application, from small diameter tubing to large diameter pipe. Whether you need a single length or multiple lengths, we have you covered. Don't see what you're looking for? Give us a call today and we'll special order it for you.

The best dealer of MS Pipe and Tubes

There are many dealers of MS pipes and tubes, but finding the best one can be a tough task. There are many factors to consider when choosing a dealer, such as their experience, reputation, prices, and customer service. With so many options out there, it can be difficult to know where to start.

Here at MS Pipe and Tube, we pride ourselves on being the best dealer of MS pipes and tubes in the business. We have years of experience in the industry and have built up a strong reputation for providing high-quality products at competitive prices. We also offer excellent customer service, so you can be sure that you're getting the best possible service when you work with us.

If you're looking for the best dealer of MS pipes and tubes, then look no further than MS Pipe and Tube. We'll provide you with the quality products and services that you need to get the job done right.

Goyal Steel Tubes one of the oldest dealer at Sahibabad

Goyal Steel Tubes is one of the oldest dealers of MS pipes and tubes in Sahibabad. The company was established in the year 1995 and is currently headed by Mr. Manoj Goyal. The company deals in all kinds of MS pipes and tubes, both seamless and welded. They also offer a wide range of other products like GI pipes, CR pipes, HR pipes, etc. The company has a very good reputation in the market and is known for its timely delivery and quality products.

How to Reach at Goyal Steel Tubes

Reaching Goyal Steel Tubes is easy as they have an online presence. They are one of the best dealers of MS pipes and tubes and are known for their quality products. You can reach them through their website or by contacting their customer care executive.

Facebook - https://www.facebook.com/goyalsteeltubes?mibextid=LQQJ4d

Instagram - https://instagram.com/goyalsteeltubes?igshid=YTY2NzY3YTc=

Contact No:- 9910495448

WhatsApp us:- 9650705448

Email Id:- [email protected]

Url- www.goyalsteeltubes.com

Conclusion

Finding the best dealer of MS Pipe and Tubes is essential for getting the materials you need to complete your projects. With so many options available, it can be hard to know which one to choose. We hope that our guide has helped you narrow down your search and find the perfect supplier for all of your steel needs. From pricing and quality control, all factors need to be considered when selecting a supplier as this will help ensure that you get the most out of your project in terms of both time and money savings.

Structural Tubes and Pipes

09/January/2023

Structural tubing and pipe are essential elements in construction projects. They provide the stability and support that buildings and other structures need. But what exactly are they? Structural tubing is a hollow section of steel that is used to support weight-bearing loads.

A pipe, on the other hand, is a tube that is used to transport liquids or gases. Both have their unique applications and benefits. In this blog post, we will explore the different uses of structural tubing and pipe. We will also discuss the benefits of each and how they can be used to improve your next construction project.

MS Pipe and Tubes

There are many different types of steel pipe and tube products on the market, each with its unique benefits and applications. But when it comes to structural tubes and pipes - the ones used in construction projects like buildings and bridges - there are three main types: MS (mild steel), HS (high strength), and CS (carbon steel).

MS pipe and tube is the most common type of structural steel tubing. It is made from low-carbon steel, meaning it has less than 0.30% carbon content. This makes it easy to weld, cut, form, and machine. It is also relatively inexpensive compared to other types of steel.

HS pipe and tube are stronger than MS, but not as easy to work with. It has a higher carbon content - between 0.60% and 1.50% - which makes it harder to weld, cut, and form. HS tubing is often used in construction projects that require high strength but don't require the same level of precision as MSpipe.

CS pipe and tube is the strongest type of structural steel tubing. It has a carbon content between 0.70% and 1.40%, making it difficult to weld, cut, or form without specialized equipment. CS tubing is often used in construction projects that require the highest levels of strength or precision.

What are Structural Tubes and Pipes?

Structural steel tubing and pipe are produced in round, square, and rectangular shapes. Round tubing is used for railings and structural support. Square and rectangular tubing are used for structural support in buildings. The pipe is usually produced in sizes from 1/8 inch to 48 inches in diameter.

Structural tubes and pipes are hollow sections that are used to provide structural support or enclose piping or wiring. They are made from a variety of materials, including aluminum, carbon steel, copper, stainless steel, and galvanized steel. A structural tube is often referred to as a hollow structural section (HSS).

Difference Between Round, Rectangular, and Square Tubes

There are three main types of structural steel tubes – round, rectangular, and square. Each has unique benefits depending on the project requirements. Here’s a quick comparison of the three:

Round Tubes:

-Rolled and welded

-Can be made from hot or cold rolled steel

-Available in a variety of diameters and wall thicknesses

-Used in everything from furniture to scaffolding

Rectangular Tubes:

-Rolled and welded or extruded

-Can be made from hot or cold rolled steel

-Available in a variety of widths and heights

-Most commonly used in construction projects, such as framing, railings, and supports

Square Tubes:

-Rolled and welded or extruded

-Can be made from hot or cold rolled steel

-Available in a variety of sizes

-Commonly used for handrails, posts, and other architectural applications

Common Uses for Structural Tubes and Pipes

There are several common uses for structural tubes and pipes, which include:

-Building construction: Tubes and pipes are often used as structural supports in the construction of buildings, bridges, and other structures.

-Machinery: Tubes and pipes are commonly used in the construction of machinery, such as agricultural equipment, exercise machines, and automotive parts.

-Furniture: Tubes and pipes are also frequently used in the construction of furniture, particularly office chairs and tables.

-Plumbing: Tubes and pipes are sometimes used in plumbing applications, such as drainpipes.

How to Choose the Right Structural Tube or Pipe for Your Project

If you are involved in a construction project, it is important to choose the right structural tube or pipe for your project. There are many factors to consider when making this decision, including the type of material, the weight of the load, the expected lifespan of the product, and the environment in which it will be used.

The type of material is one of the most important considerations when choosing a structural tube or pipe. The most common materials used for these products are steel, aluminum, and concrete. Each material has its strengths and weaknesses, so it is important to choose one that will work best for your specific application.

The weight of the load is another important factor to consider when choosing a structural tube or pipe. You need to make sure that the product you select can support the weight of the objects it will be holding. Otherwise, the product could fail and cause serious damage or injury.

The expected lifespan of the product is also an important consideration. Some products are designed for temporary use while others are meant to last for many years. If you only need a product for a short period, it might not be worth investing in a higher-quality option that would last longer. However, if you anticipate using the product for an extended period, it would be worth paying more upfront to get a better quality option that will last.

Finally, you also need to consider the environment in which the product will be used. Some products are designed for indoor

Conclusion

Whether you're looking for steel pipes, stainless steel pipes, or aluminum pipes, we've got you covered. We also offer a variety of different grades and sizes to choose from, so you can find the perfect pipe for your project. If you're not sure which type of pipe is right for you, feel free to contact us and we'll be happy to help you figure it out. Thanks for reading!

Pipe Market Sahibabad

06/February/2023

The Indian steel industry has been growing at a rapid pace with the construction sector being one of the biggest beneficiaries. One of the primary building materials used in construction is pipes, and Sahibabad, a city in the northern Indian state of Uttar Pradesh, is a major producer of mild steel pipes.

The city is widely acknowledged as a prime manufacturing hub of mild steel pipes with a significant percentage of India's total production of steel tubes and pipes coming from Sahibabad.

Evolution of Mild Steel Pipe Market

The Sahibabad region has been producing steel tubes and pipes for a substantial period, and the industry has undergone several transformations. The initial production was manual, and a small number of tubes were manufactured, mainly for irrigation and drainage purposes. However, with the opening up of the Indian economy in the early 1990s, the steel industry quickly adopted modern production techniques to meet the increasing demand for pipes.

Mild steel pipes have always been the preferred choice of construction companies due to their low cost and ability to withstand high pressure. As a result, the demand for mild steel pipes kept rising, and soon, Sahibabad became a hub of production of these popular pipes. Today, the city is home to some of the biggest producers of mild steel pipes and tubes in the country.

Mild Steel Pipe Characteristics and Uses

Mild steel pipes are an essential component in construction projects, used for diverse applications such as irrigation, water supply, drainage, and gas pipelines. They are corrosion-resistant, durable, and cheaper than pipes of other metals. Additionally, mild steel pipes are ductile, meaning they can be easily welded, bent, and formed to any desired shape; consequently, they find high usage in structural applications.

Production Process

The production of mild steel pipes involves several steps, starting from the raw material stage to the final product. The primary raw material used in production is flat-rolled steel sheets, which are first fed into a forming machine where they are bent and welded together to form a tube. The tubes are then passed through a series of rollers to ensure consistent roundness and thickness.

After the roundness and thickness have been achieved, the pipes undergo a process of cleaning and finishing, where all impurities are removed, and the surface is smoothed to give a uniform appearance. The final product is then subjected to quality checks before being dispatched to the customers.

Current Status of Sahibabad's Mild Steel Pipe Market

As of today, the Sahibabad region of India is home to many major companies engaged in manufacturing mild steel pipes. The region has experienced tremendous growth in the past few decades, and the demand for its products is expected to remain high in the coming years.

Currently, many factors are driving the growth of the steel industry in Sahibabad. One of the primary reasons is the strong demand from the construction sector, which accounts for nearly 60% of the total demand for steel products in India. As the Indian economy keeps growing, the demand for construction materials, including mild steel pipes, is expected to remain high.

Moreover, the government's emphasis on the "Make in India" campaign has further boosted the growth of the steel industry in the region. The policy aims to encourage domestic manufacturing and reduce the country's dependency on imported goods. As a result, many companies have invested in modern machines and equipment to increase their production capacity and efficiency.

Challenges Faced by Mild Steel Pipe Industry in Sahibabad

Despite the robust growth and high demand for mild steel pipes, the industry faces several challenges that affect its growth and profitability. One of the significant challenges is the inconsistent supply of raw materials, especially steel sheets. The country's steel imports have been on the rise, leading to fluctuations in prices and supply, thereby affecting the industry's cost structure.

Another major challenge is the increasing competition among manufacturers. With many players in the market, the competition is driving down prices, making it challenging for small manufacturers to remain viable. Tight margins lead some companies to resort to substandard production techniques, which affect the quality and safety of their products.

The Future of Mild Steel Pipe Production in Sahibabad

Despite the challenges, the mild steel pipe market in Sahibabad is expected to grow continually in the future. The government's initiatives to promote domestic manufacturing and increase investment in infrastructure projects are expected to fuel the demand for steel products, including mild steel pipes. The market is expected to grow at a steady CAGR of around 5.5% over the next few years.

Conclusion

Despite the challenges, the mild steel pipe industry in Sahibabad is poised for growth. With the government's focus on domestic manufacturing and the growing demand from the construction sector, the future looks bright for the industry. Moreover, the Indian steel industry has shown an ability to adopt modern production techniques and remain competitive globally. The industry is an important contributor to the country's economy, and the mild steel pipe segment is an essential part of it. The industry is expected to remain a significant force in the global steel market for years to come.

What is Structural Pipes and Tubes?

13/March/2023

Structural tubes are steel pipes that are used for various industrial, commercial, and residential applications. They are widely popular because of their strength, durability, and versatility. Structural tubes are primarily designed to withstand high stress, heavy loads, and adverse weather conditions. These tubes are extensively used in the construction of buildings, bridges, footover bridges, home fittings, and many other structural applications.

Structural Pipes: Function and Importance

Structural pipes are another popular product in the steel pipe industry. They are commonly used as load-bearing elements in building structures, which support and distribute the weight of the building, ensuring the overall integrity of the structure. Structural pipes are used in various applications, such as underground drainage systems, water supply systems, and gas pipelines. They are also used in the construction of scaffolding and support systems for building maintenance, renovation, and repair.

Steel Tubes: Types and Applications

Steel tubes come in various types and sizes, each with its unique properties and performance characteristics. Some of the common types of steel tubes used in the construction industry include cold-drawn seamless tubes, hot-rolled seamless tubes, welded tubes, galvanized tubes, and stainless steel tubes. Steel tubes are used in a wide range of applications, such as automotive, industrial machinery, construction, oil and gas, and aerospace.

One of the most significant benefits of steel tubes is their high strength-to-weight ratio, which makes them ideal for use in various structural applications. Steel tubes are also cost-effective and environmentally friendly, as they are easily recyclable and require less energy to produce. Moreover, steel tubes provide excellent resistance to corrosion, erosion, and abrasion, making them a popular choice for applications where exposure to chemicals and harsh environments is expected.

Conclusion

Structural tubes and pipes are an essential part of the building materials industry. They provide strength, durability, and versatility that are necessary in many structural applications. The steel pipe industry, building structure industry, footover bridge industry, home fitting industry, and many other industries rely significantly on structural tubes and pipes for their operations.

Industrial Steel and Tubes Materials at Pipes Market

10/April/2023

Industrial Steel and Tubes: A Key Element in the Construction Market

The construction industry and building material market depend heavily on steel, which is an essential component of construction materials, such as pipes, tubes, and fittings. Industrial steel is widely used across various industries, including automotive, aerospace, and construction. However, in today’s article, our focus is on the significance of industrial steel and tubes in construction for building materials and fittings.

Industrial Materials

Industrial materials are the essential components in the construction industry, serving as a foundation and support system for the entire structure. Industrial steel is one of the most widely used materials in the construction industry, which is of various types such as galvanized steel, carbon steel, and stainless steel. Industrial steel's durability, strength, and corrosion resistance make it a preferred material in the construction of buildings, bridges, roads, and other infrastructure projects.

The construction industry requires steel in large quantities, which explains why the market demand for industrial steel remains high, with much of it coming from the pipe and tube manufacturing sector. The industrial steel can come in different grades, lengths, sizes, and thicknesses to match the specific needs of construction projects.

Steel Tubing

Steel tubing is a specific type of industrial steel that has a hollow interior allowing fluids or gas passage, making it suitable for the construction of piping systems. Steel tubing can be round, rectangle, or square, with varying diameters, thicknesses, and lengths to satisfy different pipeline needs.

The construction industry uses steel tubing in various applications, primarily for the distribution of water, gas, or steam. Steel tubing is a more durable and robust option compared to other materials like plastic or copper used for piping systems. The tubes are resilient and can withstand high pressures and temperatures, making them ideal for extreme conditions and harsh environments.

Industrial Steel and Tubes in the Pipe Market

The pipe market is one of the major consumers of industrial steel and tubes. Pipes are used in various applications in construction, such as water and gas distribution, sewage systems, and even structural supports. Steel pipes, which are made from industrial steel, are the preferred option for most construction needs due to their many advantages over other materials.

Steel pipes are highly durable, reliable, and resistant to damage and corrosion. Pipes for buried applications are typically coated externally and internally to prevent corrosion from exposure to harsh environmental elements. Moreover, steel pipes have a longer lifespan compared to other materials, reducing the need for frequent replacement.

The pipe market for industrial steel and tubes is expected to grow in the next few years, driven primarily by the increase in the construction industry's demand. With the rising population, the need for more residential and industrial structures is a key driver for the pipe market's growth.

Conclusion

The construction industry and building material market rely heavily on steel and steel tubing, which is why industrial steel and tubes continue to be key elements in the pipe market. Steel is an ideal material for construction due to its strength, durability, and corrosion resistance. Steel tubing is especially useful in piping systems due to its ability to withstand high pressure, temperature, and harsh environments. The use of industrial steel and tubes is expected to increase, particularly in emerging markets, due to the rise in infrastructure projects. As such, the steel and tube market is expected to benefit from the increasing demand with the production of high-quality steel at reasonable prices.

What is the difference between Stainless steel pipe and Mild steel pipe?

28/October/2023

Steel pipes are a vital component in various industries, serving as conduits for transporting fluids and gases. When it comes to selecting the right type of pipe for your specific needs, two popular options emerge: stainless steel pipe and mild steel pipe. Both possess unique properties that make them suitable for different applications. In this blog post, we will explore the difference between stainless steel pipe and mild steel pipe,

shedding light on their respective characteristics, advantages, and disadvantages. So let's dive in and discover which option is best suited for your requirements!

What is Stainless Steel?

Stainless steel is a versatile and corrosion-resistant alloy that contains a minimum of 10.5% chromium. This high chromium content forms a protective layer on the surface, known as the passive film, which prevents rusting and staining. In addition to chromium, stainless steel may also contain other elements such as nickel, molybdenum, and titanium.

One of the key characteristics of stainless steel is its remarkable resistance to corrosion in various environments. This makes it an excellent choice for applications where exposure to moisture or corrosive substances is expected, such as plumbing systems or chemical processing plants.

Moreover, stainless steel exhibits exceptional strength and durability. It can withstand high temperatures without losing its structural integrity, making it suitable for use in extreme conditions like industrial furnaces or exhaust systems.

Another advantage of stainless steel is its aesthetic appeal. Its smooth and shiny surface adds a touch of sophistication to architectural designs or home decor elements.

Furthermore, stainless steel offers excellent hygiene properties due to its non-porous nature that discourages bacterial growth. This quality makes it ideal for applications in healthcare facilities or food processing industries where cleanliness is crucial.

Stainless steel's unique combination of strength, corrosion resistance, aesthetics, and hygiene make it a popular choice across various industries ranging from construction to automotive manufacturing.

What is Mild Steel?

Mild steel is a type of carbon steel that contains a low amount of carbon, making it relatively soft and malleable. It is one of the most commonly used materials in construction and manufacturing due to its affordability and versatility.

Unlike stainless steel, which has high corrosion resistance, mild steel is more prone to rusting and corroding when exposed to moisture or harsh environments. However, this can be mitigated by applying protective coatings or galvanizing the steel.

One key advantage of mild steel is its strength. It offers excellent structural integrity and can withstand heavy loads without easily deforming or breaking. This makes it ideal for applications such as building frameworks, bridges, and automotive parts.

Another benefit of using mild steel is its weldability. It can be easily welded together using various techniques, allowing for the seamless joining of different pieces to create complex structures.

Additionally, mild steel is readily available in various forms such as sheets, plates, pipes, and tubes. Its wide availability contributes to its popularity in numerous industries.

In summary,

mild steel possesses several advantageous properties such as strength,

weldability,

and availability.

Although it may not have the same level of corrosion resistance as stainless steels,

it remains a cost-effective choice for many applications requiring durability

and ease of fabrication.

Whether you are constructing a building or fabricating machinery,

consider incorporating mild steel into your project for reliable performance at an affordable price point

The difference between Stainless steel pipe and Mild Steel pipe

Stainless steel and mild steel are two common materials used in the construction industry, particularly for pipes. While they may seem similar at first glance, there are some key differences between these two types of steel.

One major difference is their composition. Stainless steel contains a high percentage of chromium, which gives it its corrosion-resistant properties. On the other hand, mild steel is primarily composed of iron and carbon, with lower levels of chromium or other alloying elements.

Another difference lies in their strength and durability. Stainless steel pipes tend to be stronger and more resistant to bending and cracking than mild steel pipes. This makes them suitable for applications where strength is crucial, such as in industrial settings or structures that require high load-bearing capacity.

In terms of appearance, stainless steel has a sleek and shiny finish due to its higher chromium content. Mild Steel pipes have a duller finish but can be easily painted or coated to enhance their aesthetics.

Cost-wise, mild steel pipes are generally cheaper compared to stainless steel pipes since they contain fewer expensive alloying elements. However, when considering long-term maintenance costs and durability, stainless

Conclusion

Both stainless steel and mild steel pipes have their own unique characteristics and applications. Stainless steel is known for its high corrosion resistance, strength, and durability, making it ideal for various industries such as construction, automotive, and manufacturing. On the other hand, mild steel is more affordable and readily available, making it suitable for general-purpose applications.

When choosing between stainless steel pipe and mild steel pipe, it's important to consider your specific requirements such as budget, environmental factors, and intended use. If you need a material that can withstand harsh conditions or corrosive environments without compromising on quality or longevity, stainless steel would be the better choice. However, if cost-effectiveness is a priority and you're looking for a versatile option that meets basic requirements in less demanding situations, mild steel would be a suitable option.

Ultimately, the decision boils down to understanding your needs, and weighing factors like cost, durability, and performance.

The right choice will ensure optimal functionality, safety, and efficiency in any project or application.

Whether you opt for stainless steel pipes or mild steel pipes, Goyal Steel Tubes provides top-quality MS pipes and Tubes products at low prices. Goyal Steel Tubes is oldest dealer at pipe market Sahibabad and the companies have branded MS pipe from the companies like: APL Apollo, Jindal, Surya, etc. they provides best quality MS pipe at low price.

With their commitment to customer satisfaction and unmatched expertise in the industry, you can trust Goyal Steel Tubes to deliver reliable solutions tailored to meet your specific needs.

Now, isn't that what truly matters when selecting the best materials?

The Ultimate Guide to Understanding MS pipes: Everything You Need to Know?

30/October/2023

Introduction

Welcome to Goyal Steel Tubes’ page to understand MS Pipes! Whether you’re a DIY enthusiast, a construction professional, or simply curious about the world of pipes and tubes, this article aims to give you all you need to know about MS Pipes. MS pipes are an integral part of various industries and applications, and it is important to have a solid understanding of their features and uses.

What is MS pipe?

MS pipes, also known as carbon steel pipes, are a type of steel pipe that is made from low-carbon content. This means that they have a relatively low amount of carbon compared to other types of steel. The low carbon content makes MS pipes more ductile and easy to work with, making them a popular choice in various industries.

One key characteristic of MS pipes is their versatility. They can be used for both structural and non-structural purposes, making them suitable for a wide range of applications. From plumbing systems to infrastructure projects and even automotive manufacturing, MS pipes play an important role in many sectors.

In terms of appearance, MS pipes typically have a dark grey or black colour due to the iron oxide scale that forms on the surface during the manufacturing process. However, this outer layer can easily be removed through cleaning or painting if desired.

When it comes to strength and durability, MS pipes offer reliable performance. They have good tensile strength and can withstand high levels of pressure without deformation or leakage. Additionally, their corrosion resistance properties make them suitable for both indoor and outdoor use.

Understanding what MS pipes are is essential for anyone working with or using these versatile components. Their affordability, durability, and ease-of-use make them an excellent choice for various applications across different industries. So whether you're involved in construction projects or simply need piping solutions at home, consider incorporating MS pipes into your plans!

The use of MS pipe is necessary in construction works, MS pipe provides strength to the structure and is available at a very low price. Its largest stock is available in Pipe Market Sahibabad because they are very oldest dealers who provide you pipes at low price.

Do you know the applications of MS pipes?

MS pipes are incredibly versatile and find applications in various industries. One of the main uses is in the construction sector, where they are used for structural purposes such as building frames, scaffolding, and fencing.

In addition to construction, MS pipes also play a crucial role in the transportation industry. They are widely used for creating pipelines that transport water, gas, and oil over long distances. These pipes are highly durable and can withstand high pressure, making them ideal for this purpose.

Another important application of mild steel pipes is in manufacturing machinery and equipment. They can be found in industries such as automotive manufacturing, agriculture, and mining. MS pipes provide strength and stability to these machines while ensuring efficient operation.

Furthermore, MS pipes are commonly utilized in plumbing systems due to their excellent corrosion resistance properties. They can effectively carry water or other fluids without any risk of leakage or contamination.

MS pipes have gained popularity in the furniture industry as well. With their sleek appearance and robustness, they are often used to create sturdy frames for chairs, tables, shelves, and more.

Overall, MS pipes have a wide range of applications across multiple sectors due to their durability, functionality, and cost-effectiveness.

These versatile products continue to contribute significantly to various industries around the world

How to buy MS pipe at low price?

When it comes to buying MS pipes at a low price, there are a few key factors to consider. It's important to do your research and compare prices from different suppliers. Look for reputable companies that offer competitive pricing without compromising on quality.

Another way to save money when purchasing MS pipes is by buying in bulk. Many suppliers offer discounts or lower rates for larger quantities, so if you have a big project coming up or anticipate needing multiple pipes in the future, this can be a cost-effective option.

Additionally, consider exploring online marketplaces and platforms where sellers offer discounted prices on MS pipes. These platforms often have various sellers competing for customers' attention, which can drive low prices.

Don't forget to negotiate with suppliers. Sometimes they may be willing to adjust their pricing if you're able to demonstrate that you're a serious buyer and potentially offering them repeat business.

By following these tips and being proactive in your search for affordable options, you'll be well on your way to finding high-quality MS pipes at a low price!

Conclusion

MS pipes are an essential component in various industries and applications. Their durability, strength, and versatility make them a popular choice for construction projects, plumbing systems, automotive manufacturing, and more. Whether you need to transport liquids or gases or require structural support for buildings or machinery, MS pipes are a reliable solution.

When purchasing MS pipes at a low price, it is crucial to consider the quality of the product along with the reputation of the supplier. Goyal Steel Tubes has been a trusted brand in Sahibabad for over 50 years and offers top-notch quality products at low prices.

Remember to assess your specific requirements before choosing the right type of MS pipe that suits your needs. Consider factors such as size, thickness, grade, and finish to ensure optimal performance and longevity.

By understanding what MS pipes are and their wide range of applications across different sectors, you can confidently make informed decisions when it comes to selecting these versatile pipes for your projects.

So next time you're in need of durable piping solutions that offer excellent value for money without compromising on quality - look no further than MS pipes! They truly are the ultimate choice for all your piping needs.

What is the difference between rejection MS pipe and fresh MS pipe?

7/November/2023

Introduction

Are you familiar with the world of MS pipes? If so, you might have heard about rejection MS pipes and fresh MS pipes. But what exactly is the difference between them? In this blog post, we will delve into the intriguing world of these two types of pipes and explore their dissimilarities. So grab a cup of coffee and join us on this fascinating journey to understand rejection MS pipe versus fresh MS pipe!

What is rejection MS pipe?

Rejection MS pipes refer to those pipes that have been deemed unfit for use after manufacturing. During the production process, companies may identify certain defects or imperfections in a batch of pipes, leading them to reject and remove these specific ones from their inventory.

These rejected pipes typically fail to meet the required standards and quality criteria set by the manufacturer. Common reasons for rejection include visible cracks, uneven thickness, surface corrosion, or other structural abnormalities that could compromise the integrity and performance of the pipe.

It is important to note that rejection does not necessarily mean these pipes are completely unusable. In fact, some companies might still find alternative purposes for them in non-critical applications where high-quality standards are not as crucial.

By identifying and removing these rejected pipes from circulation, manufacturers ensure that only top-notch products reach customers who rely on their durability and reliability. This commitment to quality control helps maintain industry standards while upholding customer satisfaction.

Rejection MS pipes are those deemed unsuitable due to various flaws detected during manufacturing. While they may serve alternate purposes in certain cases, they do not meet the desired quality benchmarks enforced by manufacturers striving for excellence in their offerings.

What is fresh MS pipe?

What is fresh MS pipe? Fresh MS pipe refers to a newly manufactured mild steel pipe that has not undergone any rejection or quality MS pipe issues. These pipes are produced using high-quality raw materials and undergo rigorous testing to ensure durability and strength.

Fresh MS pipes are made from low carbon steel, making them suitable for various applications in industries such as construction, automotive, and manufacturing. They come in different sizes and thicknesses to meet specific project requirements.

One of the key advantages of fresh MS pipes is their excellent resistance to corrosion. This makes them ideal for outdoor installations where exposure to moisture or harsh weather conditions may occur. Additionally, these pipes have good ductility, which allows for easy bending and shaping during installation.

Goyal Steel Tubes is a reputable supplier that provides both rejected and fresh MS pipes. Their commitment to quality ensures that only the finest products reach customers' hands. Whether you need rejected pipe or fresh pipe for projects, Goyal Steel Tubes has got you covered.

Fresh MS pipes offer superior durability, corrosion resistance, and versatility compared to rejected ones. Investing in high-quality piping can save time and money by avoiding potential issues down the line. Trust Goyal Steel Tubes for all your piping needs!

The difference between rejection MS pipe and fresh MS pipe

When it comes to MS pipes, there are two main categories that we often come across - rejection MS pipe and fresh MS pipe. But what exactly is the difference between these two? Let's find out!

Rejection MS pipe refers to those pipes that have been rejected by the manufacturing company for various reasons. These reasons could include defects in the material, inconsistencies in dimensions, or even issues with the surface finish. When a pipe is rejected, it means that it does not meet the required standards set by the manufacturer.

On the other hand, fresh MS pipes are just what they sound like - brand new and recently manufactured pipes. These pipes have passed all quality checks and meet all necessary specifications outlined by industry standards.

So, what sets rejection MS pipes apart from fresh ones? The most obvious difference lies in their quality and reliability. Fresh MS pipes are guaranteed to be of high quality since they have undergone rigorous testing during production. On the contrary, rejection MS pipes may have flaws or defects that make them unsuitable for certain applications.

It's important to note that while both types of pipes can be used for different purposes depending on their condition, Goyal Steel Tubes offer better performance and longevity compared to rejected ones.

Understanding the difference between rejection MS pipe and fresh MS pipe is crucial when making purchasing decisions. While rejected pipes may come at a lowest price point due to their imperfections, choosing fresh ones ensures higher quality and reliability in your projects. At Goyal Steel Tubes , we provide both options – rejection pipe and fresh pipes.

Goyal Steel Tubes is located at Pipe Market Sahibabad, Ghaziabad, Uttar Pradesh. Goyal Steel Tubes is a 50 years oldest dealer of MS pipes. They have a largest stock of MS pipes and tubes of all sizes. This is one of the best dealer of MS pipe in North India. And they have lowest price of MS pipes . Being 50 years old, it is a biggest brand today.

Conclusion

Understanding the difference between rejection MS pipes and fresh MS pipes is vital for anyone involved in the construction or manufacturing industry. Rejection MS pipes are those that have been rejected by the company after manufacturing due to certain imperfections or defects. These pipes are then removed from circulation to ensure only quality products are delivered to customers.

On the other hand, fresh MS pipes refer to those that have just been made and have not gone through any rejection process. They are considered as brand new and meet all the required specifications and standards.

The key difference between rejection MS pipes and fresh MS pipes lies in their condition - while one has been deemed unsuitable for use, the other is ready for installation without any concerns about its quality or performance.

When it comes to sourcing both types of pipe, Goyal Steel Tubes provides a wide range of options. Whether you require rejection MS pipe for specific applications where imperfections may not be a concern or fresh MS pipe for projects requiring utmost precision and reliability, they offer both choices.

Remember, it's crucial to carefully evaluate your requirements before deciding on either type of pipe. By doing so, you can ensure that your construction project proceeds smoothly with top-notch materials that deliver outstanding results.

So next time you find yourself in need of high-quality steel tubes or piping solutions, consider whether a rejection or fresh MS pipe best suits your needs – and rest assured knowing that Goyal Steel Tubes has got you covered!

Everything You Need To Know About MS Pipe Before Choosing MS Pipe Dealer

14/December/2023

MS Pipe, also known as Mild Steel Pipes, are widely used for plumbing, ventilation, and air conditioning. They offer many industrial and engineering benefits, and are mainly used in environments that contain corrosive fluids. To get the best quality, it’s important to select an experienced MS pipe Dealer. Here is a brief overview of what MS pipes have to offer.

What Are Mild Steel Pipes?

MS pipes are low carbon steel pipes. This means they contain less than 0.25% steel, making them easy to use. They are also strong, durable, hard, and weldable. The pipes can be shaped into any size or form that is suitable for tubing and pipelining.

Advantages Of MS Pipes:

Advantages of these pipes include their reusability - scrap steel can be recycled and used to create new pipes. Additionally, they are cost-effective, and their weldable nature makes them ideal for both works. The high-carbon content makes them resistant to wear, tear, and rust, while also providing high fatigue strength. Lastly, these pipes are non-corrosive and perfect for plumbing, HVAC systems, and drinking water supplies.

MS Pipe Specifications:

MS Pipes are available in:

sizes from 15NB to 900NB,

with widths of 500-2500mm

and lengths of 500-10000mm.

Some of their features include extreme strength and durability, magnetic properties, long-lasting nature, affordability, and easy fabrication.

Features of MS Pipes:

If you're interested in high-quality MS Pipes, contact Goyal Steel Tubes India. They are a renowned MS pipe Dealer, providing products that meet global standards. India also supplies their products at competitive prices.

Today, MS Pipes are used in many industries due to their impressive features. Reach out to Goyal Steel Tubes India for more information on these pipes.

The importance of communication cannot be overstated; it is essential for our relationships, our work, and even our own personal growth. Interacting with others is an indispensable part of life, and verbal communication is a key factor in making it all possible. Expressing our thoughts and feelings, as well as listening to the ideas of those around us, is a crucial element in any successful relationship. Additionally, our ability to communicate effectively is essential to our success in the workplace. It allows us to collaborate, share our knowledge, and advocate for ourselves.

Conclusion

Communication also plays a vital role in our own self-development. Through speaking and listening, we can gain insight into our own thoughts and feelings, as well as those of the people around us. In summary, communication is a fundamental part of our lives and has an important impact on our relationships, our work, and our personal growth.

Top 10 MS pipe dealers at Pipe Market Sahibabad

14/December/2023

Introduction

Welcome to the bustling world of pipe market in Sahibabad, where a myriad of options beckon those in search of top-notch MS pipes. With its thriving industrial landscape and demand for quality piping solutions, Sahibabad has become a hub for numerous MS pipe dealers. Amongst this vast sea of choices, finding the perfect dealer can be quite overwhelming.

But fret not! In this blog post, we will unveil the top 10 MS pipe dealers at the renowned pipe market Sahibabad.

MS pipe dealer at pipe market Sahibabad

Located in Sahibabad pipe market is a bustling hub of activity for those in search of high-quality MS pipes. Within this vibrant marketplace, there are numerous dealers who cater to the diverse needs of customers. One such dealer that stands out among the rest is Goyal Steel Tubes.

Goyal Steel Tubes has established itself as one of the oldest and most reliable MS pipe dealers in Sahibabad. With their extensive experience and expertise in the industry, they have gained a reputation for offering top-notch products at competitive prices.

What sets Goyal Steel Tubes apart from other dealers is their commitment to providing customers with only the best brands available. They stock renowned brands like APL Apollo and Jindal, ensuring that customers have access to superior quality MS pipes that meet their specific requirements.

In addition to offering branded products, Goyal Steel Tubes also takes pride in providing affordable options for their customers. They understand that cost-effectiveness plays a crucial role in decision-making, which is why they offer MS pipes at low prices without compromising on quality.

When it comes to finding the right MS pipe dealer for your needs, there are several factors to consider. You should look for a dealer with an extensive range of products so that you can choose from various sizes and specifications depending on your project requirements.

It's important to select a dealer who prioritizes customer satisfaction by delivering prompt service and addressing any queries or concerns promptly. This ensures a smooth purchasing experience without any unnecessary hassles.

Choosing a reputable dealer like Goyal Steel Tubes guarantees peace of mind knowing that you are investing in genuine products backed by years of trustworthiness and reliability.

With its wide range of options and dedication towards customer satisfaction, Goyal Steel Tubes emerges as one of the top MS pipe dealers at Pipe Market Sahibabad. Whether you're involved in construction projects or plumbing works - they've got all your piping needs covered! So, head over to Goyal Steel Tubes and experience their exceptional service and quality products

Top 10 MS pipe dealers at pipe market Sahibabad

If you are in the market for MS pipes, Sahibabad is a great place to start your search. With numerous dealers offering a wide range of products, you are sure to find what you need. But with so many options available, how do you choose the best dealer? To help narrow down your choices, we have compiled a list of the top 10 MS pipe dealers at Pipe Market Sahibabad.

1. Goyal Steel Tubes: One of the oldest and most reputable dealers in Sahibabad, Goyal Steel Tubes offers high-quality MS pipes at low prices.

2. LLG Ispat India: Known for their excellent customer service and extensive product range, LLG Ispat India is a trusted name in the industry.

3. Amit Sales Corporation Pvt Ltd: With a focus on providing durable and reliable MS pipes, Amit Sales Corporation Pvt Ltd is highly recommended by professionals in the field.

4. Omaxe Steel Equipments: Offering both standard and customized solutions, Omaxe Steel Equipments caters to diverse customer requirements.

5. Mahalakshmi Pipes: Mahalakshmi Pipes stands out for its commitment to delivering top-notch products on time and within budget.

6. M. B. Tubes Private Limited: Known for their prompt response and efficient service, M. B. Tubes Private Limited ensures customer satisfaction every step of the way.

7. NST Steel Tubes Pvt Ltd: NST Steel Tubes Pvt Ltd, prides itself on offering affordable yet high-quality MS pipes that meet international standards.

8. JRS Pipes and Dealers: JRS Pipes and Dealers has gained recognition for its vast inventory of MS pipes from various renowned brands like Apollo and Jindal.

9. Ajay Enterprises: Ajay Enterprises, known for its transparency and fair pricing policy, is a preferred choice among customers looking for cost-effective options without compromising quality.

10. Shivam Steels: The biggest brand product provider like Apl Apollo, Jindal etc with low price MS pipe make Shivam Steels one of reputed dealer

With these top 10 MS pipe dealers at Pipe Market Sahibabad listed, you have a starting point to find the best dealer that suits your needs.

Pros and Cons of MS pipe

MS pipes, also known as Mild Steel pipes, are widely used in various industries for their strength and durability. However, like any other material, they come with their own set of advantages and disadvantages.

One of the major pros of using MS pipes is their affordability. Compared to other types of metal pipes, MS pipes are relatively low-cost, making them a popular choice for budget-conscious buyers. Additionally, these pipes offer good tensile strength, which means they can withstand heavy loads without easily deforming or breaking.

Another advantage is that MS pipes are versatile and can be easily welded or bent into different shapes. This makes them suitable for a wide range of applications such as construction projects or plumbing systems.

On the flip side, one of the cons of using MS pipes is that they are susceptible to corrosion if not properly treated. To protect against rusting and deterioration over time due to exposure to moisture or certain chemicals, it's important to apply coatings or paint on the surface.

Furthermore, compared to some other materials like stainless steel or PVC pipes, MS pipes may have lower resistance to extreme temperatures. They can expand under high heat conditions or become brittle in freezing temperatures.

How to find the best MS pipe dealer for you

When it comes to finding the best MS pipe dealer for your needs, there are a few key factors to consider. Here are some tips to help you in your search:

1. Do your research: Start by doing thorough research on different MS pipe dealers in your area. Look for their reputation, experience, and customer reviews.

2. Quality products: Ensure that the dealer offers high-quality MS pipes from trusted brands like Apl Apollo, Jindal, etc. The quality of the pipes is crucial for durability and performance.

3. Competitive pricing: Compare prices from different dealers to ensure you get the best deal without compromising on quality. Goyal Steel Tubes is known for offering lowest prices on their MS pipes.

4. Wide range of options: Look for a dealer who has a diverse range of MS pipes available in various sizes, thicknesses, and specifications. This will ensure that you find the right pipe for your specific requirements.

5. Trustworthy customer service: Opting for a dealer with excellent customer service can make all the difference when it comes to after-sales support or addressing any concerns or queries you may have during the purchasing process.

6. Speedy delivery: Check if the dealer offers prompt delivery services so that you can receive your order within a reasonable timeframe.

Remember these points as you embark on finding the best MS pipe dealer for yourself!

Conclusion

In this article, we have explored the top 10 MS pipe dealers in the pipe market Sahibabad. These dealers are known for their exceptional quality products and customer service. Whether you are in need of pipes for industrial or residential purposes, these dealers can cater to all your requirements.

Amongst these renowned dealers, Goyal Steel Tubes stands out as one of the oldest and most trusted names in the industry. With a wide range of branded products like Apl Apollo, Jindal, and more, they offer high-quality MS pipes at lowest prices. Their commitment to delivering value and satisfaction to customers has made them a popular choice among buyers.

What is MS Pipe?

08/January/2024

Introduction

Mild Steel, often referred to as MS, is a type of metal that’s used to make various things, and one of those things is MS Pipes. Let’s break it down in simple terms.

What is Mild Steel?

Mild Steel is a type of metal that's strong and not easily broken. It's made by adding a little bit of carbon to iron. This mix makes it tough but still flexible, and that's why it's used in many things, including pipes.

What are MS Pipes?

MS Pipes are tubes made from Mild Steel. Think of them as long, hollow cylinders. These pipes are used for many purposes, like carrying liquids, gases, or even as structural parts in buildings and bridges. The reason MS Pipes are so popular is that Mild Steel is strong and can handle different types of conditions without easily getting damaged.

How are MS Pipes Made?

Making MS Pipes involves a process called welding. Welding is like joining pieces of metal together using heat. The Mild Steel is shaped into a pipe, and then the edges are welded to create a strong connection. This process ensures that the pipe can carry things without any leaks or breaks.

Why Use MS Pipes?

MS Pipes have become a go-to choice for many reasons:

Strength: Mild Steel is known for its strength, making the pipes sturdy and reliable.

Affordability: MS Pipes are cost-effective, making them a practical choice for many projects.

Versatility: These pipes can be used for various purposes – from transporting water to supporting structures.

Where are MS Pipes Used?

MS Pipes have a wide range of uses:

Water Supply: They are used to carry water from one place to another in homes, industries, and cities.

Construction: MS Pipes play a crucial role in building structures like houses, bridges, and even large buildings.

Oil and Gas: In industries, MS Pipes are used to transport oil and gases safely.

Fencing: They are also used for creating fences around homes or fields.

Taking Care of MS Pipes:

While MS Pipes are strong, they still need some care:

Painting: Painting MS Pipes helps protect them from rust, which can weaken the metal.

Regular Checks: Periodic checks for any signs of damage ensure that the pipes remain in good condition.

Conclusion:

In simple terms, MS Pipes are strong tubes made from a type of tough metal called Mild Steel. They're like the unsung heroes, working quietly behind the scenes in our daily lives, whether carrying water, supporting buildings, or transporting important liquids. Understanding what they are and how they work can help us appreciate the strength and versatility that MS Pipes bring to the world around us.

MS Pipe at Sahibabad Ghaziabad

08/January/2024

Introduction

In Sahibabad, Ghaziabad, there’s a lot happening, and one thing you might notice are these strong tubes called MS Pipes. Let’s take a stroll through the basics to understand what they are and why they matter.

What are MS Pipes?

MS Pipes, or Mild Steel Pipes, are like the quiet heroes of construction and transportation. They are sturdy tubes made from a tough metal called Mild Steel. Now, let's break it down a bit.

Why are They Important in Sahibabad?

Sahibabad is a buzzing place with buildings, industries, and homes. MS Pipes play a crucial role here for a few simple reasons:

Building Strong Structures: In Sahibabad, where new buildings pop up and old ones stand tall, MS Pipes are used to create the strong skeletons that hold everything together. Whether it's a home or a big building, these pipes provide the support needed.

Carrying Important Stuff: Imagine all the things we need every day – water, gas, and more. MS Pipes make sure these things travel safely from one place to another without any leaks. So, when you turn on the tap for water in Sahibabad, you can thank these pipes!

Supporting Industries: Industries in Sahibabad often need to move liquids like oil and gases. MS Pipes come to the rescue, helping transport these important substances safely.

How are MS Pipes in Sahibabad Made?

Making MS Pipes is like creating a superhero – it involves a bit of magic! Okay, not really magic, but it's a cool process called welding. Welding is like a superhero handshake for metal. The Mild Steel is shaped into a pipe, and then the edges are welded together. This creates a super-strong connection that can handle all kinds of jobs without breaking a sweat.

Why Choose MS Pipes in Sahibabad?

People in Sahibabad love using MS Pipes for a few simple reasons:

Strength for Sahibabad's Busy Life: Life in Sahibabad is bustling, and things need to be strong to keep up. MS Pipes, with their tough Mild Steel, provide the strength required for all the action.

Affordability for Smart Choices: In Sahibabad, where smart choices matter, MS Pipes are a hit because they're strong and pocket-friendly. They get the job done without breaking the bank.

Versatility for Diverse Needs: Whether it's carrying water, supporting a building, or transporting important stuff, MS Pipes in Sahibabad are versatile. They can handle different tasks without breaking a sweat.

Taking Care of MS Pipes in Sahibabad:

Now, just like any superhero, MS Pipes need a bit of care to keep saving the day:

Painting for Protection: A good coat of paint is like a superhero cape for MS Pipes. It protects them from rust, ensuring they stay strong and reliable.

Regular Checks for Health: Sahibabad is a busy place, and regular health checks for MS Pipes are a must. This way, any signs of trouble can be spotted early, and the pipes can be kept in good shape.

Conclusion:

Next time you walk through Sahibabad, take a moment to appreciate the strength and reliability of MS Pipes. They might not wear capes, but these strong tubes are silently working behind the scenes, making life in Sahibabad a little more comfortable and a lot more secure. From building structures to ensuring a smooth flow of important things, MS Pipes are the unsung heroes of Sahibabad's bustling landscape.

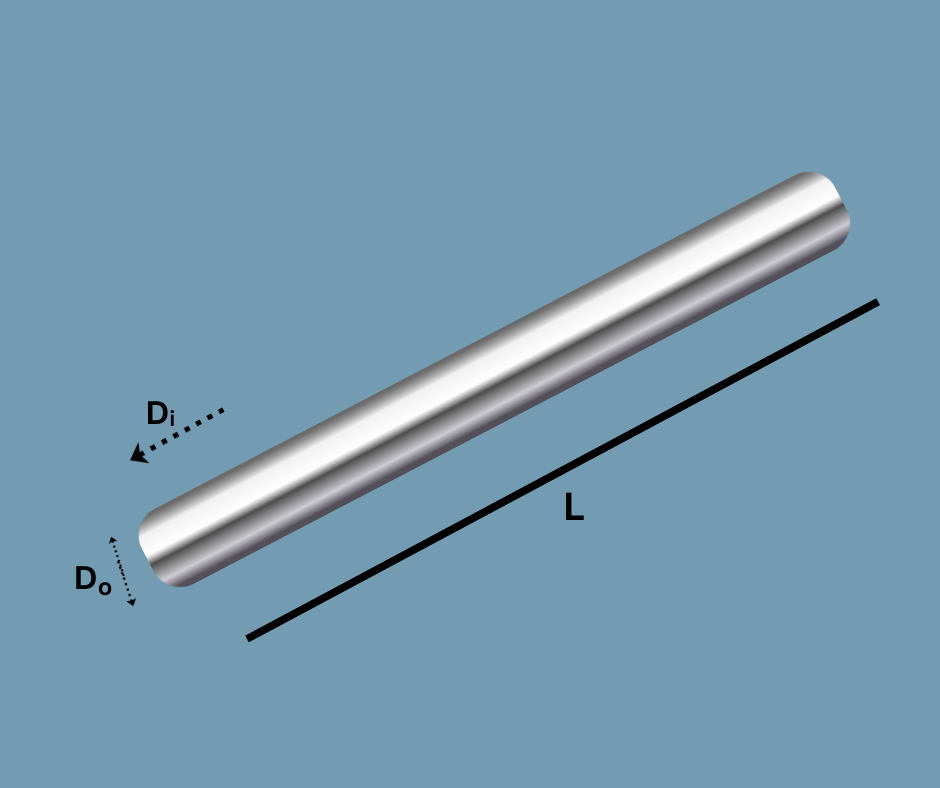

MS Pipe weight

10/January/2024

Introduction

In the realm of construction and industrial applications, understanding the weight of materials is paramount. When it comes to MS (Mild Steel) Pipes, their weight is a critical factor that influences everything from structural integrity to transportation and installation. Let’s delve into the intricacies of MS Pipe weight, exploring why it matters and how it is calculated.

Why Does MS Pipe Weight Matter?

• Structural Considerations:

In construction projects, whether it's building a residential structure or a towering skyscraper, the weight-bearing capacity of materials is of utmost importance. MS Pipes form an integral part of these structures, contributing to their stability and strength.

• Transportation and Handling:

The weight of MS Pipes directly impacts the logistics of transportation and handling. Whether being transported to a construction site or within a manufacturing facility, knowing the weight helps in planning and executing safe and efficient logistics operations.

• Installation Planning:

During the installation phase, contractors and engineers need precise information about the weight of MS Pipes. This knowledge guides decisions related to equipment requirements, lifting mechanisms, and overall installation processes.

• Load Distribution:

Understanding the weight of MS Pipes is crucial for engineers and architects when designing foundations and support structures. Proper load distribution ensures that the entire system can withstand the stresses imposed by the weight of the pipes.

Factors Influencing MS Pipe Weight:

Nominal Bore Size:

The nominal bore size of the MS Pipe, which refers to its inner diameter, is a key factor. Larger bore sizes typically result in heavier pipes.

Wall Thickness:

The thickness of the pipe walls significantly contributes to its weight. Thicker walls provide increased strength but also add to the overall weight of the pipe.

Length of the Pipe:

The length of the MS Pipe is a straightforward factor. Longer pipes naturally weigh more than shorter ones. This is particularly crucial for transportation considerations.

Type of MS Steel

The specific type of mild steel used in the pipe influences its density, thereby impacting the overall weight. Different grades of MS steel may have varying weights for the same nominal bore size and wall thickness.

Calculating MS Pipe Weight:

The weight of an MS Pipe can be calculated using a simple formula:

Weight (kg) = (π/4) × Nominal Bore Size (mm)2 ×

(Outer Diameter (mm) - Inner Diameter (mm)) ×

Density of Mild Steel (g/cm3) × 0.001

In this formula:

π is a mathematical constant (approximately 3.14159).

The outer diameter and inner diameter are measured in millimetres.

The density of mild steel is typically around 7.85 g/cm³.

This formula takes into account the cross-sectional area of the pipe and the density of the material to provide an accurate estimation of the pipe's weight.

Understanding the Weight Class of MS Pipes:

MS Pipes are often categorized into different weight classes based on their thickness. The weight class is denoted by a schedule number. Common weight classes include Schedule 40 and Schedule 80. Higher schedule numbers indicate thicker walls and, consequently, heavier pipes. Engineers and builders select the appropriate weight class based on the structural requirements of the project.

Managing MS Pipe Weight in Practical Applications:

• Transportation Planning:

For transportation, especially over long distances, knowing the weight of MS Pipes is crucial for selecting the right vehicles and ensuring compliance with weight restrictions on roads.

• Handling and Installation:

During construction, precise information about the weight of MS Pipes guides decisions related to cranes, hoists, and other lifting equipment. It also aids in planning the installation process to ensure safety and efficiency.

• Load Distribution in Structures:

Engineers use the weight information to distribute loads evenly in structures, preventing overloading on specific points and ensuring the overall stability of the construction.

• Cost Estimation:

The weight of MS Pipes is a factor in cost estimation. Heavier pipes may require more robust support structures and incur higher transportation costs.

Challenges and Considerations:

• Corrosion Impact:

While weight is a critical consideration, factors such as corrosion resistance should not be overlooked. Coatings and treatments can add weight but also enhance the longevity of the pipes.

• Environmental Impact:

In environmentally sensitive projects, the ecological impact of transporting heavy materials may be a consideration. Sustainable practices may influence material choices.

Conclusion:

In the world of construction and industry, where precision and efficiency are paramount, understanding the weight of MS Pipes is a fundamental aspect of project planning. From the initial design phase to transportation, installation, and structural considerations, the weight of MS Pipes influences numerous facets of construction projects. Engineers, architects, and project managers rely on accurate weight calculations to ensure the success and safety of their endeavours. As technology advances and sustainable practices gain prominence, finding a balance between weight considerations and other environmental and structural factors becomes even more critical. Ultimately, the weight of MS Pipes is not just a numerical value; it's a crucial element in the symphony of construction and engineering, shaping the landscapes we live and work in.

MS Pipe HSN Code

10/January/2024

Introduction

In the complex world of trade and commerce, every product is assigned a specific code for seamless identification and classification. For Mild Steel (MS) Pipes, this code is known as the Harmonized System of Nomenclature (HSN) Code. Let’s unravel the significance of the MS Pipe HSN Code and its role in international trade and taxation.

What is HSN Code?

The Harmonized System of Nomenclature (HSN) Code is an internationally accepted system for the classification of products in trade. Developed by the World Customs Organization (WCO), the HSN Code comprises a series of numerical codes assigned to different products, facilitating uniformity and clarity in international trade transactions.

HSN Code for MS Pipes:

The HSN Code for MS Pipes specifically classifies them within the broader category of iron and steel products. The code is determined based on various factors, including the type of metal, dimensions, and other distinguishing features. For MS Pipes, the HSN Code falls under Chapter 73 of the HSN Code structure, which covers articles of iron or steel.

Significance of MS Pipe HSN Code:

International Trade:

In the global marketplace, where goods cross borders seamlessly, the HSN Code serves as a universal language. It ensures that MS Pipes are recognized and classified consistently across different countries, facilitating smoother international trade.

Customs and Tariffs:

Customs authorities use the HSN Code to determine the appropriate tariffs and duties for imported and exported goods. The code streamlines the customs clearance process and aids in accurate taxation based on the nature and characteristics of the product.

Uniform Classification:

The HSN Code provides a standardized method for classifying MS Pipes, eliminating ambiguity and ensuring that all parties involved in a trade transaction have a clear understanding of the product being traded.

Structure of MS Pipe HSN Code:

The HSN Code for MS Pipes typically follows a numerical structure. The first two digits represent the chapter under which the product falls, and subsequent digits provide more specific details about the product. For example, the HSN Code for MS Pipes might look something like this:

HSN Code for MS Pipes: The subsequent digits further specify the type of iron or steel product, including dimensions, coatings, or other distinguishing characteristics.

Application in GST:

In the context of the Goods and Services Tax (GST) in India, the HSN Code plays a crucial role. Businesses use the HSN Code while filing their GST returns, providing detailed information about the goods they have traded. For MS Pipe manufacturers, traders, and distributors, correctly classifying their products under the relevant HSN Code ensures compliance with GST regulations.

Determining the Correct HSN Code for MS Pipes:

Material Composition:

The type of material used in the MS Pipes, in this case, mild steel, is a key factor in determining the HSN Code. Different materials fall under different chapters and codes within the HSN structure.

Dimensions and Specifications:

The dimensions, thickness, and specifications of the MS Pipes influence the finer details of the HSN Code. These specifics help in narrowing down the code to accurately represent the product.

Coating or Treatment:

If the MS Pipes have undergone any special coating or treatment, this information is considered in the HSN Code assignment. Coatings may include galvanization or other protective measures.

Use and Application:

The use and application of MS Pipes can also influence their classification. Whether they are intended for construction, industrial use, or other specific applications may impact the assigned HSN Code.

Benefits of Accurate HSN Code Classification:

Legal Compliance:

Accurate classification under the appropriate HSN Code ensures legal compliance with international trade regulations and GST requirements.

Facilitates Trade Documentation:

The HSN Code simplifies trade documentation, making it easier for businesses to convey precise information about their products in a standardized format.

Tariff Determination:

Customs authorities rely on the HSN Code to determine applicable tariffs and duties. Correct classification avoids disputes and delays in customs clearance.

GST Reporting:

Businesses use the HSN Code while reporting their GST transactions. Accurate reporting contributes to transparent and efficient tax compliance.

Conclusion: